Bury it, don’t burn it: turning biomass waste into a carbon solution

If a tree fell in a forest almost 4000 years ago, did it make a sound? Well, in the case of an Eastern red cedar in what is now Quebec, Canada, it’s certainly still making noise today.

That’s because in 2013, a team of scientists were digging a trench when they came across the 3775-year-old log. Despite being buried for nearly four millennia, the wood wasn’t rotten and useless. In fact, recent analysis unearthed an entirely different story.

The team, led by atmospheric scientist Ning Zeng of the University of Maryland in the US, found that the wood had only lost 5% of its carbon compared with a freshly cut Eastern red cedar log. “The wood is nice and solid – you could probably make a piece of furniture out of it,” says Zeng. The log had been preserved in such remarkable shape because the clay soil it was buried in was highly impermeable. That limited the amount of oxygen and water reaching the wood, suppressing the activity of micro-organisms that would otherwise have made it decompose.

This ancient log is a compelling example of “biomass burial”. When plants decompose or are burnt, they release the carbon dioxide (CO2) they had absorbed from the atmosphere. One idea to prevent this CO2 being released back into the atmosphere is to bury the waste biomass under conditions that prevent or slow decomposition, thereby trapping the carbon underground for centuries.

In fact, Zeng and his colleagues discovered the cedar log while they were digging a huge trench to bury 35 tonnes of wood to test this very idea. Nine years later, when they dug up some samples, they found that the wood had barely decomposed. Further analysis suggested that if the logs had been left buried for a century, they would still hold 97% of the carbon that was present when they were felled.

Digging holes

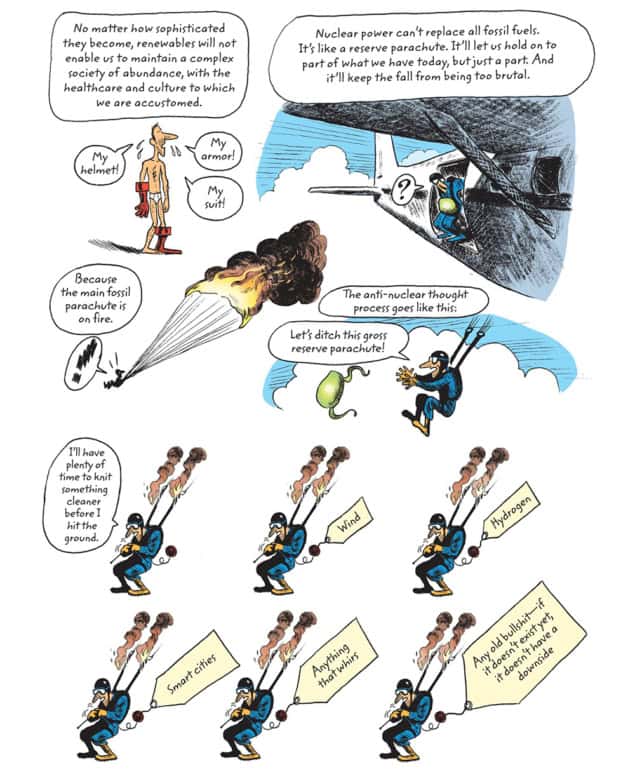

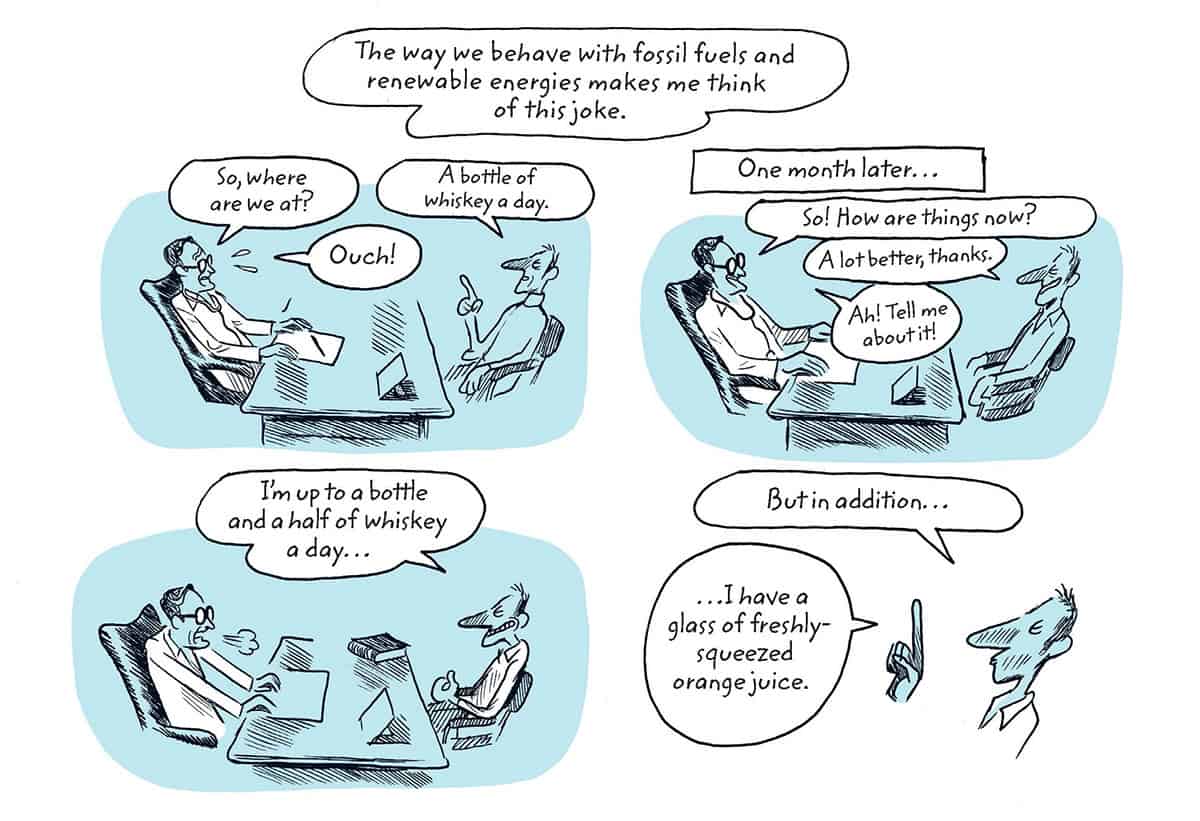

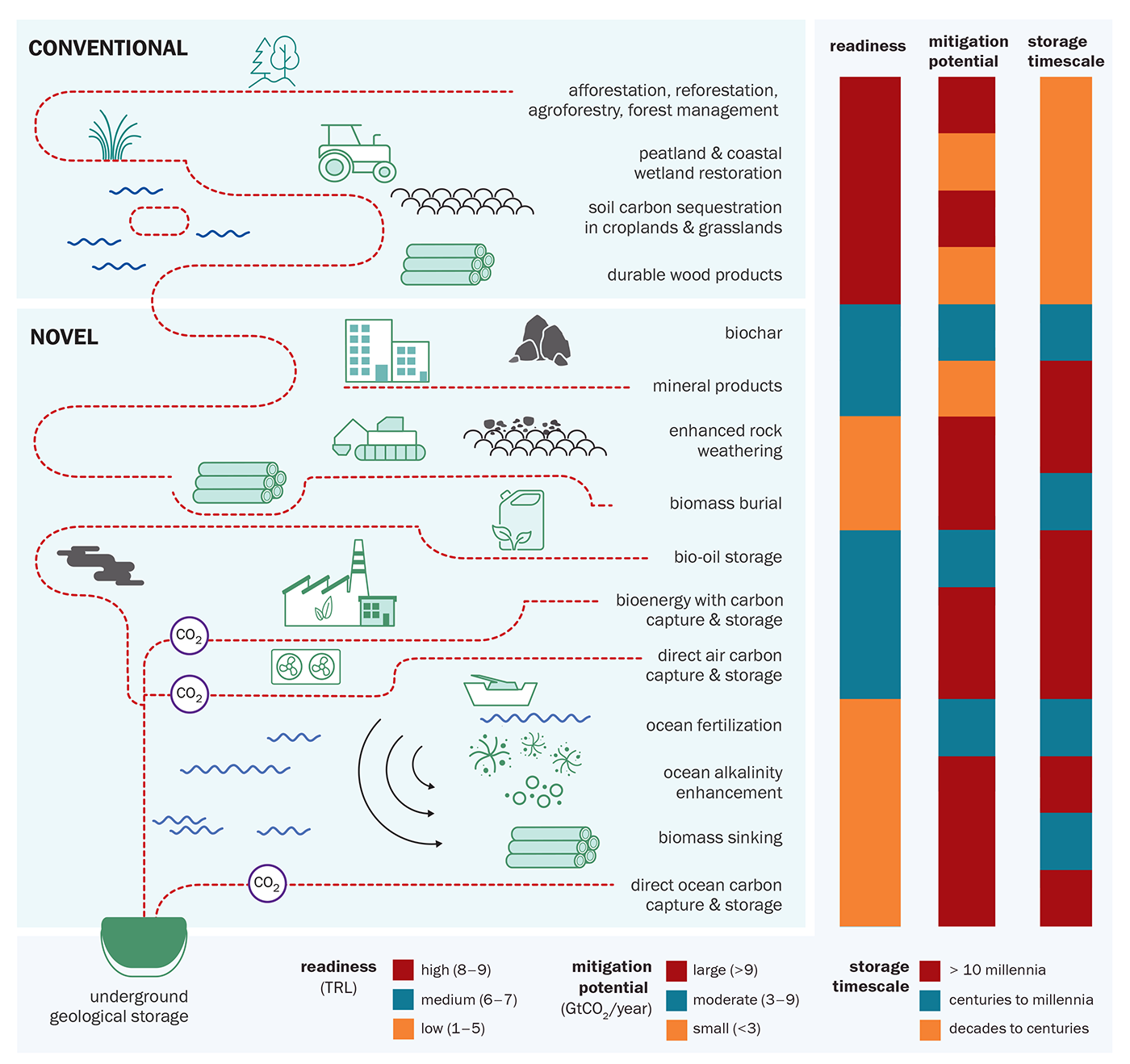

To combat climate change, there is often much discussion about how to remove carbon from the atmosphere. As well as conventional techniques like restoring peatland and replanting forests, there are a variety of more technical methods being developed (figure 1). These include direct air capture (DAC) and ocean alkalinity enhancement, which involves tweaking the chemistry of oceans so that they absorb more CO2. But some scientists – like Sinéad Crotty, a managing director at the Carbon Containment Lab in Connecticut, US – think that biomass burial could be a simpler and cheaper way to sequester carbon.

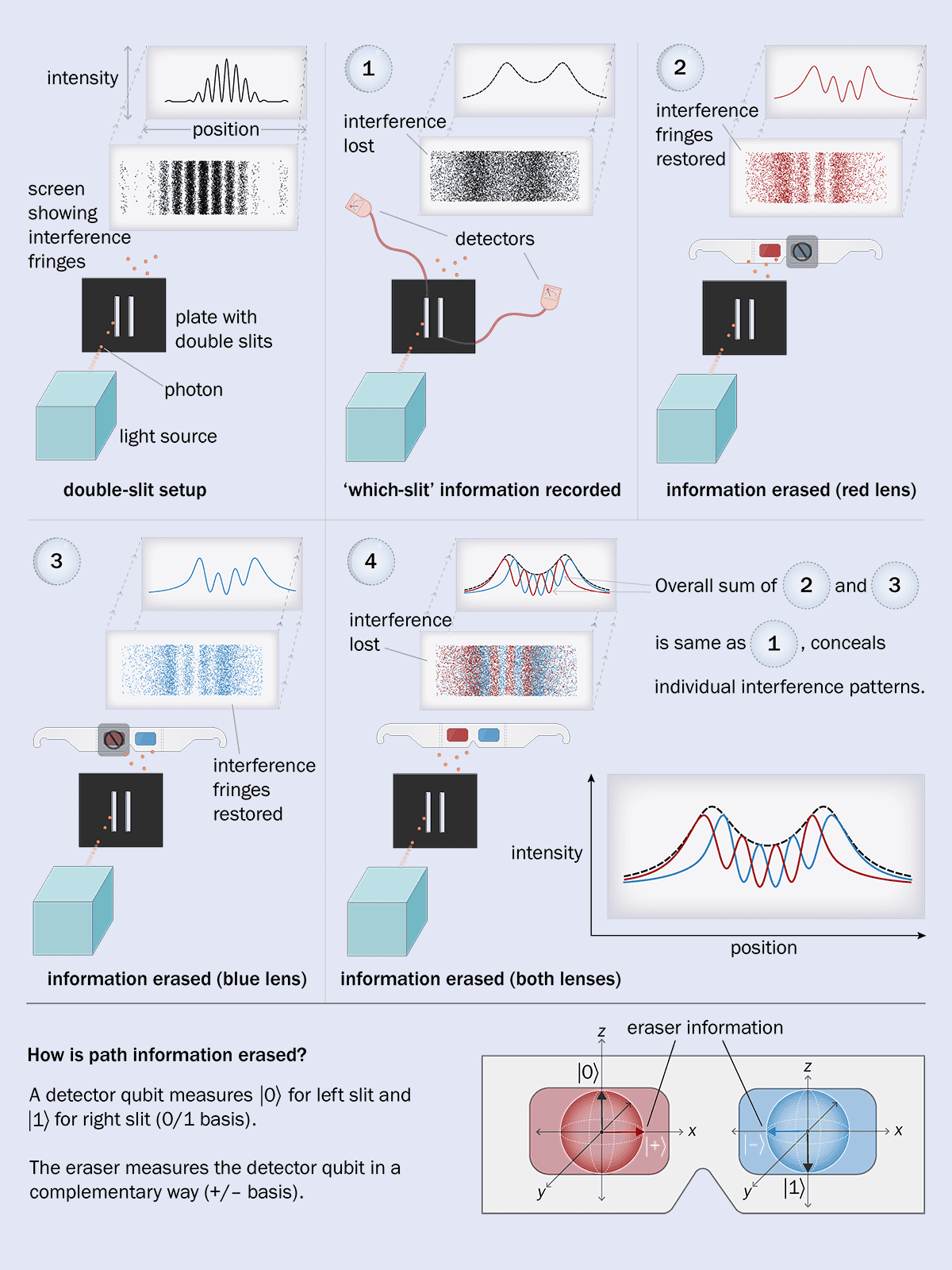

1 Ready or not

There are multiple methods being developed for capturing, converting and storing carbon dioxide (CO2), each at different stages of readiness for deployment, with varying removal capabilities and storage durability timescales.

This figure – adapted from the State of Carbon Dioxide Removal report – shows methods that are already deployed or analysed in research literature. They are categorized as either “conventional”, processes that are widely established and deployed at scale; or “novel”, those that are at a lower level of readiness and therefore only used on smaller scales. The figure also rates their Technology Readiness Level (TRL), maximum mitigation potential (how many gigatonnes (109 tonnes) of CO2 can be sequestered per year), and storage timescale.

The report defines each technique as follows:

- Afforestation – Conversion to forest of land that was previously not forest.

- Reforestation – Conversion to forest of land that was previously deforested.

- Agroforestry – Growing trees on agricultural land while maintaining agricultural production.

- Forest management – Stewardship and use of existing forests. To count as carbon dioxide removal (CDR), forest management practices must enhance the long-term average carbon stock in the forest system.

- Peatland and coastal wetland restoration – Assisted recovery of inland ecosystems that are permanently or seasonally flooded or saturated by water (such as peatlands) and of coastal ecosystems (such as tidal marshes, mangroves and seagrass meadows). To count as CDR, this recovery must lead to a durable increase in the carbon content of these systems.

- Durable wood products – Wood products which meet a given threshold of durability, typically used in construction. These can include sawn wood, wood panels and composite beams, but exclude less durable products such as paper.

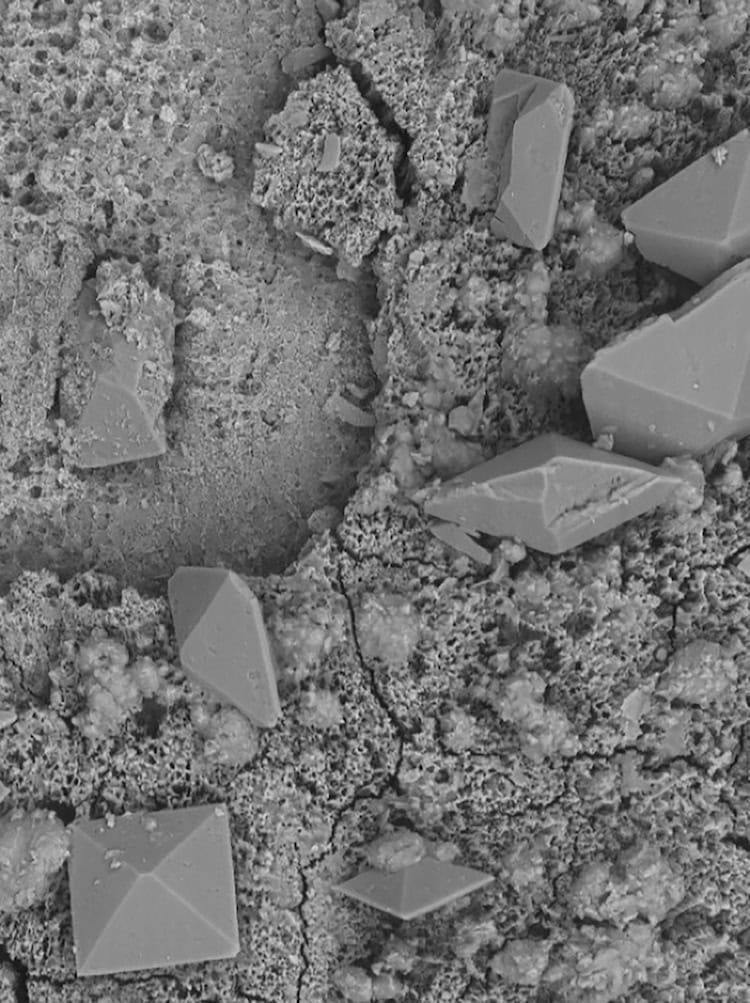

- Biochar – Relatively stable, carbon-rich material produced by heating biomass in an oxygen-limited environment. Assumed to be applied as a soil amendment unless otherwise stated.

- Mineral products – Production of solid carbonate materials for use in products such as aggregates, asphalt, cement and concrete, using CO2 captured from the atmosphere.

- Enhanced rock weathering – Increasing the natural rate of removal of CO2 from the atmosphere by applying crushed rocks, rich in calcium and magnesium, to soil or beaches.

- Biomass burial – Burial of biomass in land sites such as soils or exhausted mines. Excludes storage in the typical geological formations associated with carbon capture and storage (CCS).

- Bio-oil storage – Oil made by biomass conversion and placed into geological storage.

- Bioenergy with carbon capture and storage – Process by which biogenic CO2 is captured from a bioenergy facility, with subsequent geological storage.

- Direct air carbon capture and storage – Chemical process by which CO2 is captured from the ambient air, with subsequent geological storage.

- Ocean fertilization – Enhancement of nutrient supply to the near-surface ocean with the aim of sequestering additional CO2 from the atmosphere stimulated through biological production. Methods include direct addition of micro-nutrients or macro-nutrients. To count as CDR, the biomass must reach the deep ocean where the carbon has the potential to be sequestered durably.

- Ocean alkalinity enhancement – Spreading of alkaline materials on the ocean surface to increase the alkalinity of the water and thus increase ocean CO2 uptake.

- Biomass sinking – Sinking of terrestrial (e.g. straw) or marine (e.g. macroalgae) biomass in the marine environment. To count as CDR, the biomass must reach the deep ocean where the carbon has the potential to be sequestered durably.

- Direct ocean carbon capture and storage – Chemical process by which CO2 is captured directly from seawater, with subsequent geological storage. To count as CDR, this capture must lead to increased ocean CO2 uptake.

The 3775-year-old log shows that carbon can be stored for centuries underground, but the wood has to be buried under specific conditions. “People tend to think, ‘Who doesn’t know how to dig a hole and bury some wood?’” Zeng says. “But think about how many wooden coffins were buried in human history. How many of them survived? For a timescale of hundreds or thousands of years, we need the right conditions.”

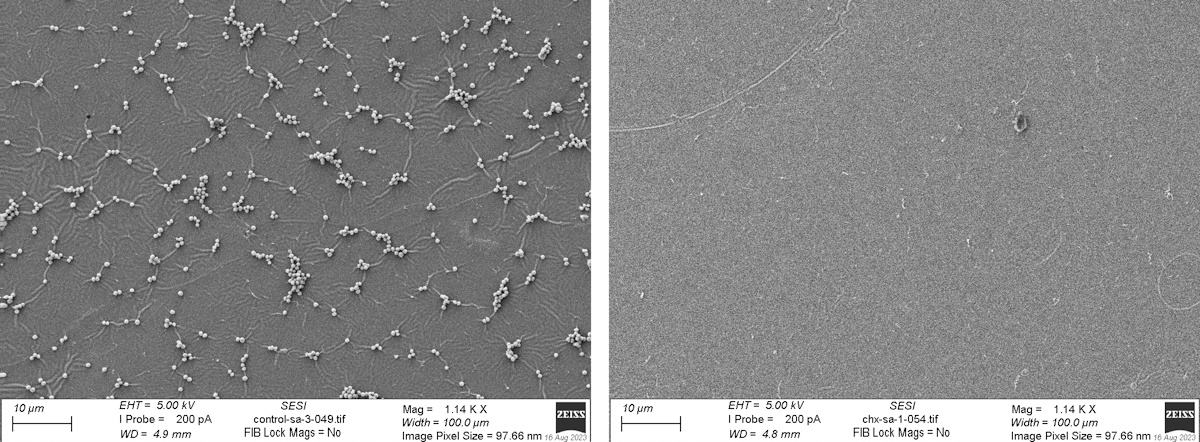

The key for scientists seeking to test biomass burial is to create dry, low-oxygen environments, similar to those in the Quebec clay soil. Last year, for example, Crotty and her colleagues dug more than 100 pits at a site in Colorado, in the US, filled them with woody material and then covered them up again. In five years’ time they plan to dig the biomass back out of the pits to see how much it has decomposed.

The pits vary in depth, and have been refilled and packed in different ways, to test how their build impacts carbon storage. The researchers will also be calculating the carbon emissions of processes such as transporting and burying the biomass – including the amount of carbon released from the soil when the pits are dug. “What we are trying to do here is build an understanding of what works and what doesn’t, but also how we can measure, report and verify that what we are doing is truly carbon negative,” Crotty says.

Over the next five years the team will continuously measure surface CO2 and methane fluxes from several of the pits, while every pit will have its CO2 and methane emissions measured monthly. There are also moisture sensors and oxygen probes buried in the pits, plus a full weather station on the site.

Crotty says that all this data will allow them to assess how different depths, packing styles and the local environment alter conditions in the chambers. When the samples are excavated in five years, the researchers will also explore what types of decomposition the burial did and did not suppress. This will include tests to identify different fungal and bacterial signatures, to uncover the micro-organisms involved in any decay.

The big questions

Experiments like Crotty’s will help answer one of the key concerns about terrestrial storage of biomass: how long can the carbon be stored?

In 2023 a team led by Lawrence Livermore National Laboratory (LLNL) did a large-scale analysis of the potential for CO2 removal in the US. The resulting Road to Removal report outlined how CO2 removal could be used to help the US achieve its net zero goals (these have since been revoked by the Trump administration), focusing on techniques like direct air capture (DAC), increasing carbon uptake in forests and agricultural lands, and converting waste biomass into fuels and CO2.

The report did not, however, look at biomass burial. One of the report authors, Sarah Baker – an expert in decarbonization and CO2 removal at LLNL – told Physics World that this was because of a lack of evidence around the durability of the carbon stored. The report’s minimum requirement for carbon storage was at least 100 years, and there were not enough data available to show how much carbon stored in biomass would remain after that period, Baker explains.

The US Department of Energy is also working to address this question. It has funded a set of projects, which Baker is involved with, to bridge some of the knowledge gaps on carbon-removal pathways. This includes one led by the National Renewable Energy Lab, measuring how long carbon in buried biomass remains stored under different conditions.

Bury the problem

Crotty’s Colorado experiment is also addressing another question: are all forms of biomass equally appropriate for burial? To test this, Crotty’s team filled the pits with a range of woody materials, including different types of wood and wood chip as well as compressed wood, and “slash” – small branches, leaves, bark and other debris created by logging and other forestry work.

Indeed, Crotty and her colleagues see biomass storage as crucial for those managing our forests. The western US states, in particular, have seen an increased risk of wildfires through a mix of climate change and aggressive fire-suppression policies that do not allow smaller fires to burn and thereby produce overgrown forests. “This has led to a build-up of fuels across the landscape,” Crotty says. “So, in a forest that would typically have a high number of low-severity fires, it’s changed the fire regime into a very high-intensity one.”

These concerns led the US Forest Service to announce a 10-year wildfire crisis plan in 2022 that seeks to reduce the risk of fires by thinning and clearing 50 million acres of forest land, in addition to 20 million acres already slated for treatment. But this creates a new problem.

“There are currently very few markets for the types of residues that need to come out of these forests – it is usually small-diameter, low-value timber,” explains Crotty. “They typically can’t pay their way out of the forests, so business as usual in many areas is to simply put them in a pile and burn them.”

A recent study Crotty co-authored suggests that every year “pile burning” in US National Forests emits greenhouse gases equivalent to almost two million tonnes of CO2, and more than 11 million tonnes of fine particulate matter – air pollution that is linked to a range of health problems. Conservative estimates by the Carbon Containment Lab indicate that the material scheduled for clearance under the Forest Service’s 10-year crisis plan will contain around two gigatonnes (Gt) of CO2 equivalents. This is around 5% of current annual global CO2 emissions.

There are also cost implications. Crotty’s recent analysis found that piling and burning forest residue costs around $700 to $1300 per acre. By adding value to the carbon in the forest residues and keeping it out of the atmosphere, biomass storage may offer a solution to these issues, Crotty says.

As an incentive to remove carbon from the atmosphere, trading mechanisms exist whereby individuals, companies and governments can buy and sell carbon emissions. In essence, carbon has a price attached to it, meaning that someone who has emitted too much, say, can pay someone else to capture and store the equivalent amount of emissions, with an often-touted figure being $100 per tonne of CO2 stored. For a long time, this has been seen as the price at which carbon capture becomes affordable, enabling scale up to the volumes needed to tackle climate change.

“There is only so much capital that we will ever deploy towards [carbon removal] and thus the cheaper the solution, the more credits we’ll be able to generate, the more carbon we will be able to remove from the atmosphere,” explains Justin Freiberg, a managing director of the Carbon Containment Lab. “$100 is relatively arbitrary, but it is important to have a target and aim low on pricing for high quality credits.”

DAC has not managed to reach this magical price point. Indeed, the Swiss firm Climeworks – which is one of the biggest DAC companies – has stated that its costs might be around $300 per tonne by 2030.

A tomb in a mine

Another carbon-removal company, however, claims it has hit this benchmark using biomass burial. “We’re selling our first credits at $100 per tonne,” says Hannah Murnen, chief technology officer at Graphyte – a US firm backed by Bill Gates.

Graphyte is confident that there is significant potential in biomass burial. Based in Pine Bluff, Arkansas, the firm dries and compresses waste biomass into blocks before storage. “We dry it to below a level at which life can exist,” says Murnen, which effectively halts decomposition.

The company claims that it will soon be storing 50,000 tonnes of CO2 per year and is aiming for five million tonnes per year by 2030. Murnen acknowledges that these are “really significant figures”, particularly compared with what has been achieved in carbon capture so far. Nevertheless, she adds, if you look at the targets around carbon capture “this is the type of scale we need to get to”.

The need for carbon capture

The Intergovernmental Panel on Climate Change says that carbon capture is essential to limit global warming to 1.5 °C above pre-industrial levels.

To stay within the Paris Agreement’s climate targets, the 2024 State of Carbon Dioxide Removal report estimated that 7–9 gigatonnes (Gt) of CO2 removal will be needed annually by 2050. According to the report – which was put together by multiple institutions, led by the University of Oxford – currently two billion tonnes of CO2 are being removed per year, mostly through “conventional” methods like tree planting and wetland restoration. “Novel” methods – such as direct air capture (DAC), bioenergy with carbon capture, and ocean alkalinity enhancement – contribute 1.3 million tonnes of CO₂ removal per year, less than 0.1% of the total.

Graphyte is currently working with sawmill residue and rice hulls, but in the future Murnen says it plans to accept all sorts of biomass waste. “One of the great things about biomass for the purpose of carbon removal is that, because we are not doing any sort of chemical transformation on the biomass, we’re very flexible to the type of biomass,” Murnen adds.

And there appears to be plenty available. Estimates by researchers in the UK and India (NPJ Climate and Atmospheric Science 2 35) suggest that every year around 140 Gt of biomass waste is generated globally from forestry and agriculture. Around two-thirds of the agricultural residues are from cereals, like wheat, rice, barley and oats, while sugarcane stems and leaves are the second largest contributors. The rest is made up of things like leaves, roots, peels and shells from other crops. Like forest residues, much of this waste ends up being burnt or left to rot, releasing its carbon.

Currently, Graphyte has one storage site about 30 km from Pine Bluff, where its compressed biomass blocks are stored underground, enclosed in an impermeable layer that prevents water ingress. “We took what used to be an old gravel mine – so basically a big hole in the ground – and we’ve created a lined storage tomb where we are placing the biomass and then sealing it closed,” says Murnen.

Once sealed, Graphyte monitors the CO2 and methane concentrations in the headspace of the vaults, to check for any decomposition of the biomass. The company also analyses biomass as it enters the facility, to track how much carbon it is storing. Wood residues, like sawmill waste are generally around 50% carbon, says Murnen, but rice hulls are closer to 35% carbon.

Graphyte is confident that its storage is physically robust and could avoid any re-emission for what Murnen calls “a very long period of time”. However, it is also exploring how to prevent accidental disturbance of the biomass in the future – possibly long after the company ceases to exist. One option is to add a conservation easement to the site, a well-established US legal mechanism for adding long-term protection to land.

“We feel pretty strongly that the way we are approaching [carbon removal] is one of the most scalable ways,” Murnen says. “In as far as impediments or barriers to scale, we have a much easier permitting pathway, we don’t need pipelines, we are pretty flexible on the type of land that we can use for our storage sites, and we have a huge variety of feedstocks that we can take into the process.”

A simple solution

Back at LLNL, Baker says that although she hasn’t “run the numbers”, and there are a lot caveats, she suspects that biomass burial is “true carbon removal because it is so simple”.

Once associated upstream and downstream emissions are taken into account, many techniques that people call carbon removal are probably not, she says, because they emit more fossil CO2 than they store.

Biomass burial is also cheap. As the Road to Removal analysis found, “thermal chemical” techniques, like pyrolysis, have great potential for removing and storing carbon while converting biomass into hydrogen and sustainable aviation fuel. But they require huge investment, with larger facilities potentially costing hundreds of millions of dollars. Biomass burial could even act as temporary storage until facilities are ready to convert the carbon into sustainable fuels. “Buy ourselves time and then use it later,” says Baker.

Either way, biomass burial has great potential for the future of carbon storage, and therefore our environment. “The sooner we can start doing these things the greater the climate impact,” Baker says.

We just need to know that the storage is durable – and if that 3775-year-old log is any indication, there’s the potential to store biomass for hundreds, maybe thousands of years.

The post Bury it, don’t burn it: turning biomass waste into a carbon solution appeared first on Physics World.